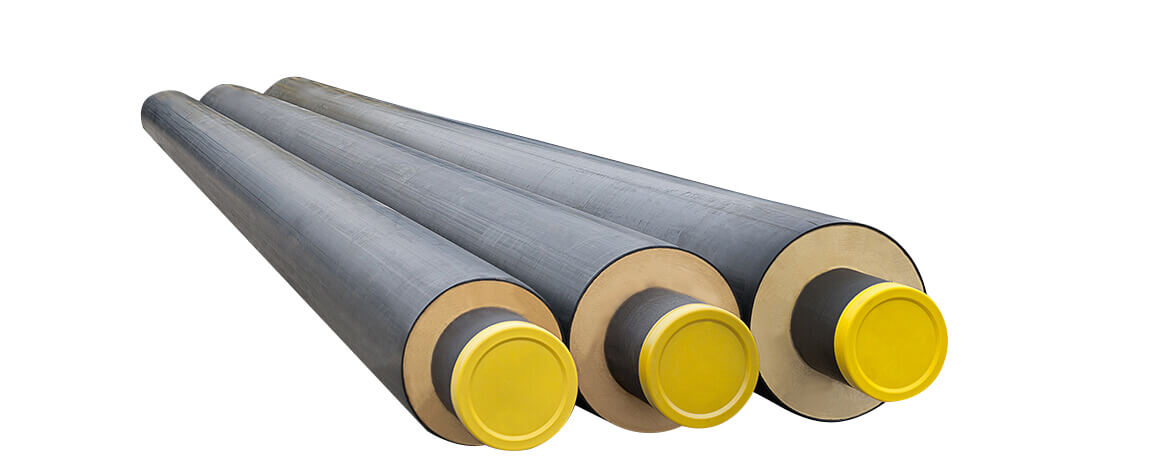

With its high quality and ease of use, Kuzeyboru pre-insulated pipes are produced with the highest technology in accordance with international standards (TS EN 253, TS EN 448, TS EN 2201 2 + A1). Thermal expansion stresses are absorbed by the use of polyurethane foam between the carrier pipe and the casing pipe and transmits the friction force between the earth and the outer pipe to the carrier pipe. Thanks to this feature, it eliminates the need for compactors.

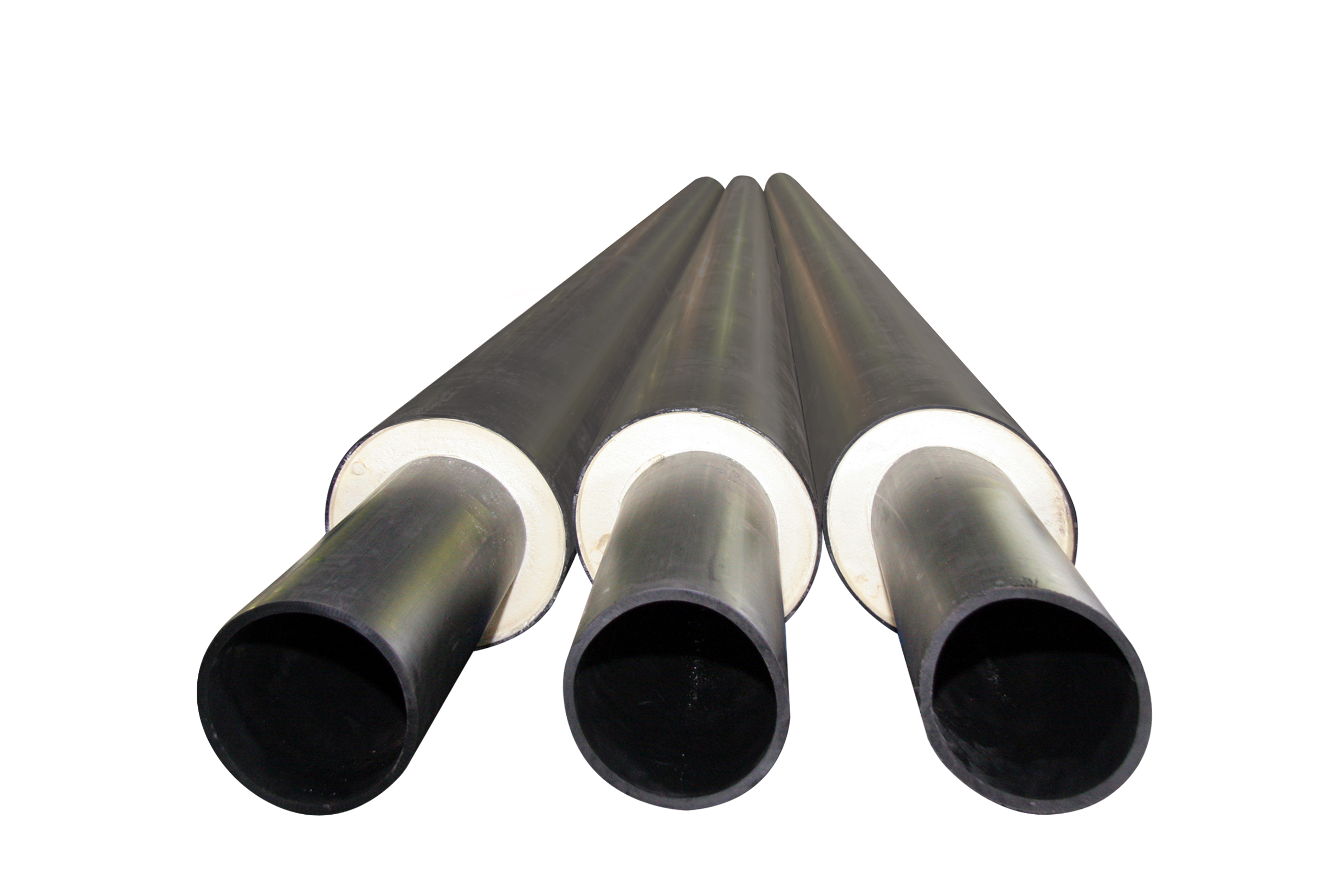

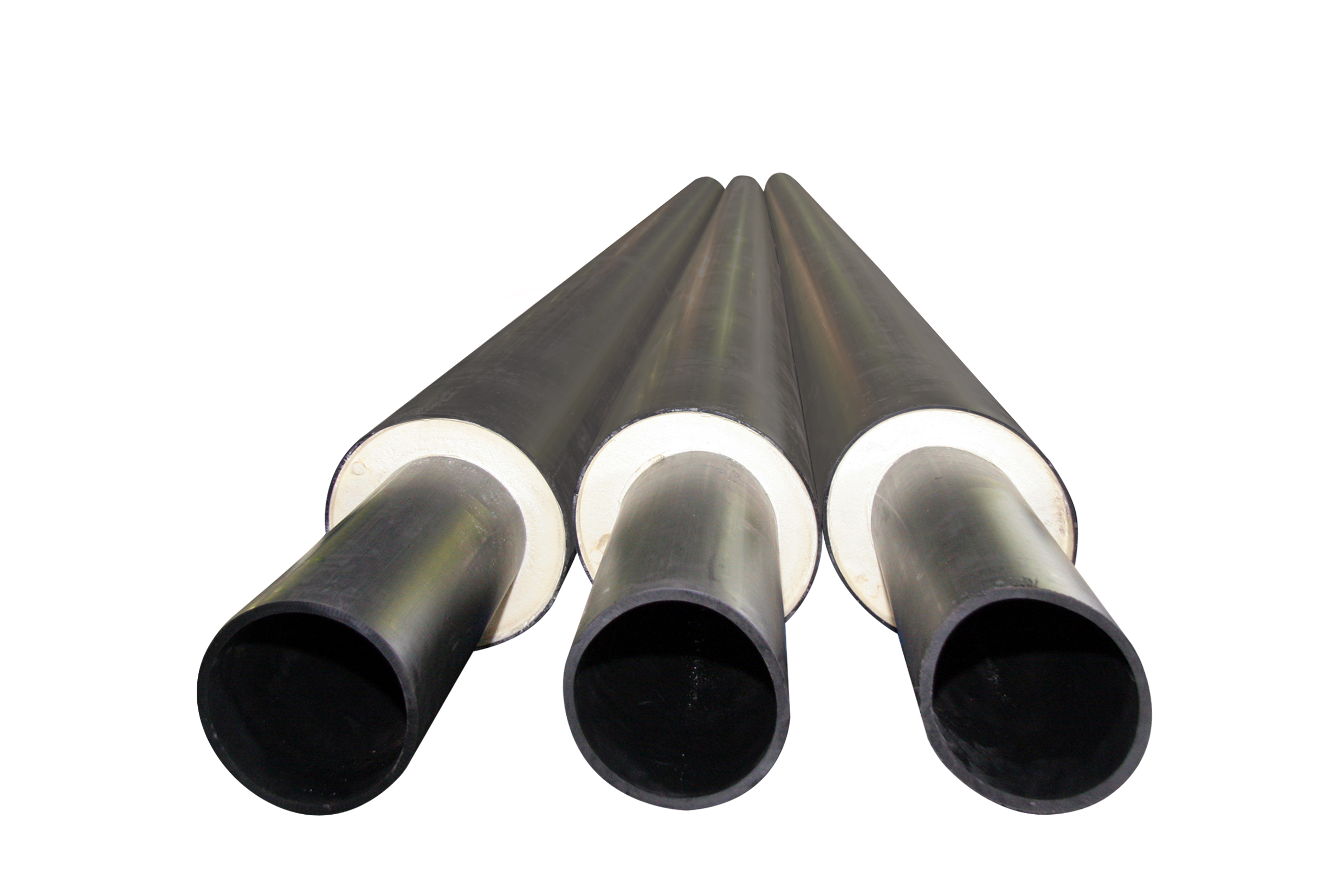

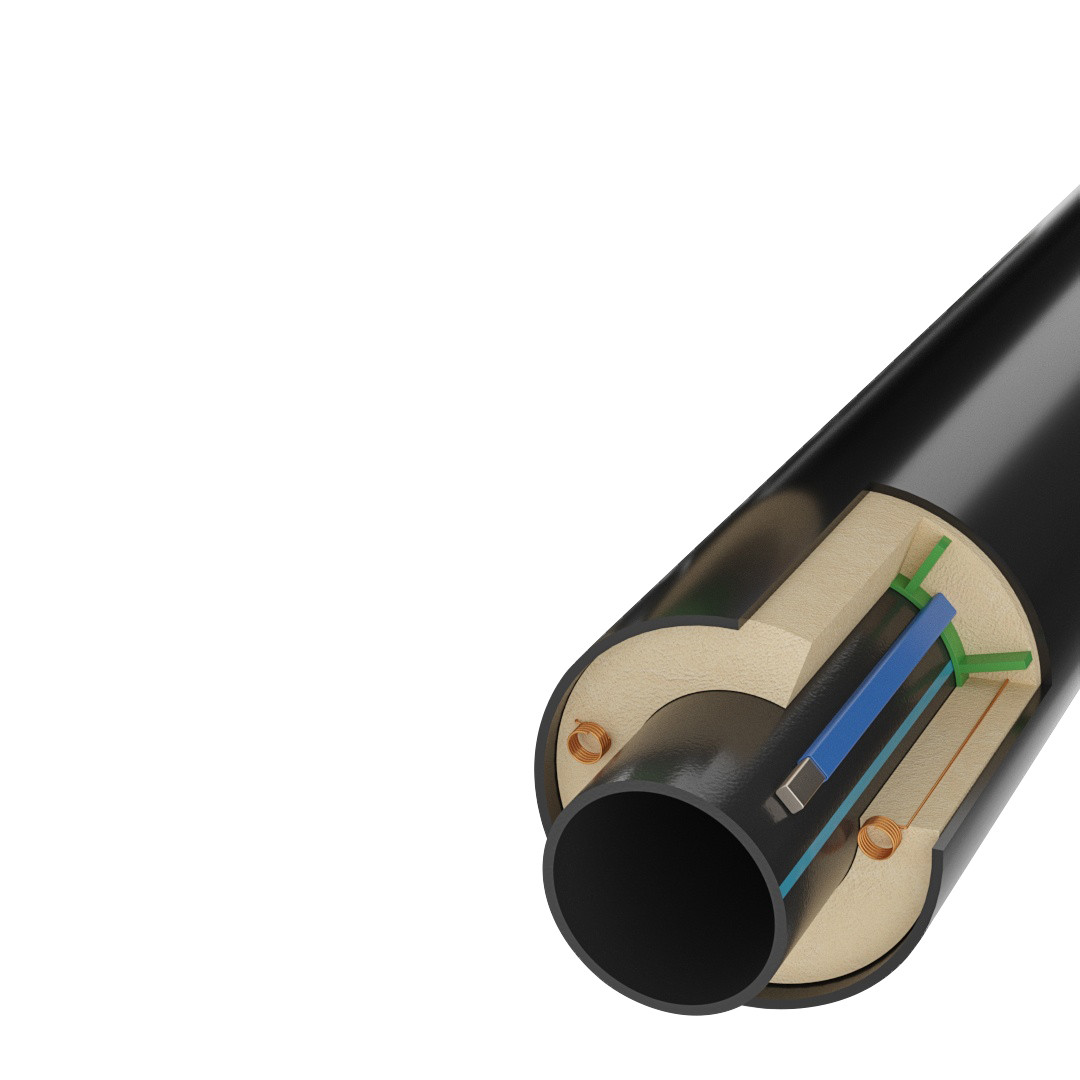

In the production of our pre-insulated pipes, the inner part of the pipe consists of high density polyethylene. In the second layer, polyurethane foam is used in accordance with the volume of the pipe. On the last layer, there is also a protective cover made of high density polyethylene.PUR: The polyurethane material used in Kuzeyboru pre-insulated pipes is supplied from companies that produce in accordance with EN 253 norm.Since the cell structure is closed, it does not take in water.It provides heat savings due to its thermal conductivity coefficient (50 °) <0.026 W / (mK).In accordance with TS EN 253, the foam core density is at least 60 kg / m3, and the overall density is ≥80 kg / m3. Compressive strength is 0.3 N / mm2 and axial shear strength 0.12 N / mm2. Shear strength along the circumference is 0.20 N / mm2 ‘.It can be processed continuously with fluids at temperatures up to 120˚C and the peak temperature of fluids may rise up to 140˚C from time to time.

Carrier Pipe

In standard production, the carrier pipe is made of steel and is resistant up to 140 ºC water temperature.Sheath pipes; Kuzeyboru casing pipes are produced with 100% original HDPE 100 raw material according to TS EN 12201-2 + A1 standard. It stands out with its high resistance to abrasion and resistance to impacts.

Advantages of Kuzeyboru Pre-Insulated Pipes

• Heat loss during transfer is at a minimum level.

• Provides ease of use, transportation and assembly.

• It is resistant to corrosion.

• It has a lifetime of more than 50 years under 120 ° C continuous temperature.

• Due to the heat conduction coefficient of the polyurethane used, there is less heat loss compared to the classical system.Because the sheath pipe is HDPE, it provides 100% sealing.

• There is no need for any cost-increasing operations such as reinforced concrete, channel, gallery, support.

• The laying time is easier than the classical system.

• It provides homogeneity in isolation thickness.

• Pipes and fittings are produced according to TS EN 253, TS EN 448, TS EN 12201-2 + A1 and tested in our laboratory.

Kuzeyboru Pre-Insulated Pipe Usage Areas

In geothermal district heating and cooling projects,In fire lines,In central heating systems, satellite cities, sites,In gallery or underground applications,In industrial facilities,In greenhouse applications,On gas and oil lines,Hotels and tourism applications,In universities,In military facilities,In water lines,It is used in ship installations and in many areas.

Use In Ship Industry

KUZEYBORU pre-insulated pipes provide many advantages to your projects. With the developing technology, this approach has been developed for the design and installation of pre-insulated pipe systems in ship applications. This approach is applied in the renewal of the existing lines on the ships as well as in the new ships. Pre-insulated piping is an ideal solution in order not to be affected by salt water coming from the effect of waves, strong wind, rain, heat and human traffic.

Usage Advantages Of Northpipe Pre-Insulated Pipes In Ship Industry

• Resistance to temperature range from -200 to + 315 ° C

• No energy losses

• Using HDPE sheath pipes due to its resistance to chemicals and UV rays

• Resistance of carrier pipes against corrosion

• Easy and quick to build

Ensuring good environmental safety

Low repair cost