HDPE Pipe Manufacturer and Supplier - Kuzeyboru

Hdpe Pipe is produced by Kuzeyboru with its high quality and many advantages. Kuzeyboru Hdpe Pipes, which are the most preferred in international projects, are ideal for a wide variety of applications. We produce Kuzeyboru Hdpe Pipes in desired diameters between 20 mm - 1600 mm and in Pn4-Pn32 pressure classes with high performance and quality. Hdpe Pipe systems that you can safely use in your projects offer many advantages.

What is High-Density Polyethylene Pipe?

HDPE Pipe produced from polyethylene has become popular with its advantages, high strength and wide usage area. Hdpe Pipe has many advantages. It has become the best choice for projects with the reliability of pipes and fittings, ease of transportation and loading, and ease of assembly. Polyethylene Pipes show high resistance against impact and pressure. It has high chemical resistance. These features have been the most important reason for the preference of polyethylene pipes and polyethylene fittings.

So what distinguishes HDPE from other products? HDPE pipe is strong, durable, flexible and lightweight. Because the fusion process creates a monolithic HDPE system, HDPE has a zero leakage rate when combined. HDPE pipe is also a more environmentally sustainable option as it is non-toxic, resistant to corrosion and chemicals, has a long design life and is ideal for trenchless installation methods due to its flexibility.

Advantages of Hdpe Pipe

1- Easy assembly method and easy assembly of fittings.

2- It is not affected by underground movements and is not broken.

3- It has high impact resistance and rapid crack propagation.

4- They have high flexibility properties. Thus, they provide ease of use.

5- Since they have low internal surface roughness, they have significant advantages in diameter selection during project design.

6- It is not affected by sea water and sea movements, it is suitable for mounting on the sea floor.

7- Black colored pipes are resistant to UV rays. They are not affected by harmful substances.

8- It is found in the structure of the soil that causes abrasive effects. They are resistant to chemicals.

9- They do not change the smell and taste of water, so they can be used safely in drinking water.

10- It is not possible for plant and tree roots to get inside.

Applications of HDPE Pipes

Hdpe Pipes are used safely in many projects with their high strength and quality. Hdpe Tubing, which is the most preferred in infrastructure systems, has a wide usage area. Hdpe Pipe usage areas;

Drinking Water Pipelines, Pressure Irrigation Pipelines, Hydroelectric Power Plants, Gas Lines, Treatment Plant Pipeline, Water Treatment Plant, Swimming Pools Pipeline, Chilled Water Pipeline, Compressed Air Lines, Solid Material Handling Lines, Chemical Pipeline, Geothermal Coating Heating Pipes, Sewer Pipelines, Solid Waste Methane Gas Discharge Line, Solid Waste Drainage Line, Marine Discharge Pipe Line, Fish Farm Pipe line

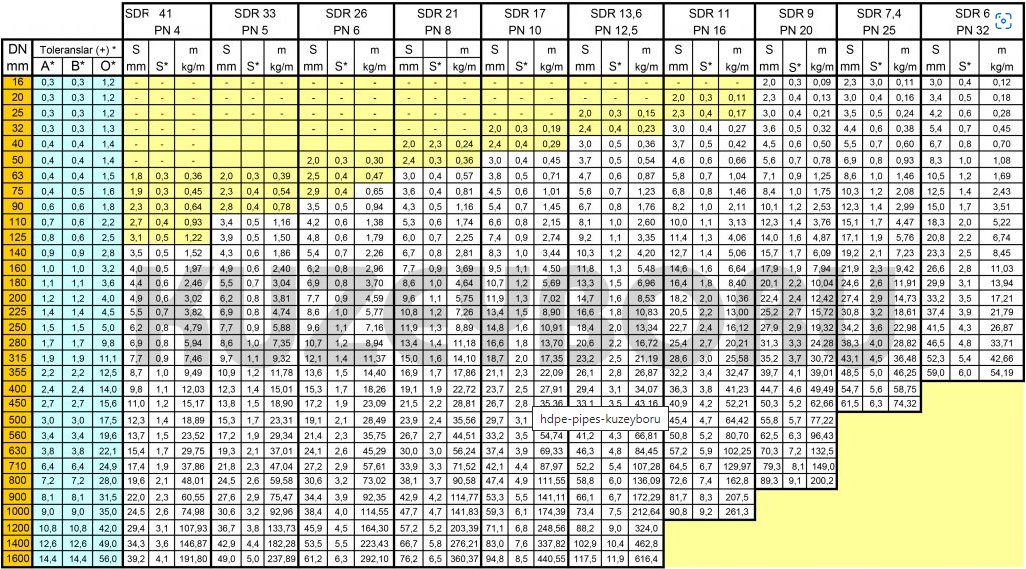

Hdpe Pipes Weight Technical Table

Kuzeyboru Hdpe Pipe weight table, also known as Kuzeyboru Polyethylene Pipe, offers an extensive hdpe pipe sizes and hdpe pipe weight chart. This comprehensive resource provides accurate measurements and weight details for different hdpe pipe sizes.

By multiplying the density of the Hdpe pressure pipe by the volume of the hollow cylinder, the weight of each hdpe pipe can be determined. It is important to note that during the production phase, the Hdpe pipes undergo heat treatment, which introduces expansion characteristics.

Therefore, when creating the Hdpe pipe measurement table, it is crucial to consider tolerance values for precise calculations. With the hdpe pipe sizes and hdpe pipe weight chart available, you can easily select the appropriate pipe size and ensure accurate weight estimation for your specific requirements.

Hdpe Pipe Fittings

Hdpe pipe fittings play a crucial role in creating efficient and reliable piping systems. These fittings are specifically designed for use with high-density polyethylene (HDPE) pipes and offer numerous advantages.

One of the main benefits of HDPE pipe fittings is their versatility. They are available in a wide range of configurations, including elbows, tees, reducers, couplers, and flange adapters, allowing for seamless integration into different piping layouts.

HDPE pipe fittings are easy to install and require minimal maintenance. Their lightweight construction and simple jointing methods, such as heat fusion or mechanical connections, streamline the installation process and reduce labor costs.

HDPE Pipe Installation

Kuzeyboru Polyethylene pipes and fittings are connected to each other by melting or mechanical fittings. The Hdpe pipes made from materials other than polyethylene can be connected to the outside with squeezed inserts, flanges or other suitable adapters made for the purpose. Connection fittings provide convenience compared to the places to be used.

Combinations Methods

• Electrofusion (EF) Welding Type

.webp)

.webp)

Electrofusion Welding

The principle of the electrofusion welding method is to fuse copper wires in the plugged parts from the parts to be combined with the Electrofusion Welding Machine by melting a certain part of the outer parts of the two parts by heating them with electricity. Pe100 pipes can be welded by Electrofusion welding method up to diameter of 20 mm up to 1200 mm. The electrofusion welding method is carried out in accordance with DVS 2207 standard.

Butt – Welding

The most common welding method used today is the joining of Hdpe pipe and fittings by Butt Welding Method. The joining method is connect the ends of pipes to be welded by using butt welding machine and both ends are pushed toward each other by pressing under a certain temperature. The pipes of up to 1200 mm diameter can be welded by using the welding method. The butt welding is made in accordance with DVS 2207 standard.

Hdpe Pipe Laying Rules

Hdpe Pipe laying methods should be done as specified in the standards. Hdpe Pipes add speed to your project with the advantage of easy assembly and laying.

✓ PE pipes are laid inside the channel after welding.

✓ Pipes that are damaged or crushed during transportation or storage should never be used.

✓ There should be no puddles in the channel where the pipes will be laid.

✓ Sand, gravel, mixed sand should be used as filling material.

✓ The minimum channel depth will be 70-80 cm.

✓ After covering the top of the pipe, the filling will be completed by compressing it with medium force.

Hdpe Pipe Technical Specifications

As KUZEYBORU we are closely monitoring developments in our quality laboratori and conducting continuous researches. Kuzeyboru Pe Pipe are produced in the highest technology and quality from 20 mm to 1200 mm diameters.

The properties of polyethylene, it is one of the best alternative among the pipe types used in pressurized clean water systems. They are used in the construction of underground and overhead pressurized water network lines, marine discharge projects, fish production farm production cages.

Hdpe Pipe Price List 2023

Looking for the latest prices on HDPE pipes in 2023? Look no further than Kuzeyboru! As a leading manufacturer and supplier of HDPE pipes, we are committed to providing our customers with the highest quality products at competitive prices.

Our 2023 HDPE pipe price list includes a wide range of sizes and specifications to meet the needs of any project. From small-scale residential applications to large-scale industrial projects, we have the right HDPE pipes for your needs.

Our HDPE pipes are made from high-density polyethylene (HDPE) material, which is known for its durability, flexibility, and resistance to corrosion and chemical damage. With a long lifespan of up to 50 years, our pipes provide a reliable and cost-effective solution for a wide range of applications.

Contact us today to learn more about our HDPE pipe products and pricing options. Our experienced sales team is ready to assist you in selecting the right products for your specific needs and budget.

Hdpe Pipe Blog

This blog will help you learn more about HDPE pipe and fittings supplier and manufacturer Kuzeyboru.

What are Hdpe Pipe Joining Methods

This blog will help you learn more technical information about Hdpe Pipe joining methods.

Hdpe Pipes Weight Technical Table

This blog will help you learn more about Hdpe Pipe weight chart and pipe diameters.

©

What is Polyethylene Pipe used for?

This blog will help you learn more about polyethylene pipe, its uses, features, advantages, price.

.png)

The Kuzeyboru Hdpe Pipe is produced from the beginning to the end with superior technological infrastructure.

.png)

Kuzeyboru Polyethylene Pipes safely in your projects with durability and proven 100-year lifespan.

.png)

Kuzeyboru provides its customers with the best service and provides the production with 100% original raw material.

.png)

Kuzeyboru production from the beginning to the end , our engineers makes all the tests and controlled at our accredited pipe laboratory in the every stage.

.png)

Kuzeyboru Hdpe Pipe produces solutions suitable for your projects and be near of the every prosess on production.

_(6).png)

Kuzeyboru Hdpe Pipes will be indispensable for your projects with high quality and reasonable price. Get in touch immediately.

Hdpe pipe is one of the most commonly used plastics in the construction industry. It’s lightweight, easy to work with and can be easily molded into any shape. Hdpe pipe comes in a variety of different styles and sizes. It’s commonly used in residential and commercial applications, including water pipes, sewer pipes, storm water drains and waste lines.

Hdpe pipe is also used for industrial uses, such as food-processing piping, cooling system piping and other uses.

Hdpe pipe can be made from HDPE or LDPE plastic. HDPE has a higher tensile strength than LDPE, which makes it more resistant to wear and tear. HDPE can also withstand more heat than LDPE.

---

PE100 pipe is a kind of plastic pipe made of high density polyethylene. It has good chemical resistance, high tensile strength and good impact resistance. PE100 pipe can be used in water, gas and other pipelines.

It can withstand high pressure, tensile force and temperature extremes. It’s widely used as heat transfer media, such as electrical cable insulation, power transmission line insulation, oil pipeline insulation and so on.

We offer PE100 pipe with different thicknesses: 0.5-1mm, 1-3mm. The main application is for pipelines with domestic hot water heating systems.

It is widely used to deliver hot water to homes and offices.

---

Polyethylene is a clear plastic with a high melting point and a low coefficient of friction. It is resistant to heat and impact, has good strength and stiffness, and can be easily extruded. PE pipe undergoes a high temperature process, which is also the most common method to produce PE products. It has excellent chemical resistance, high impact resistance, low permeability and low permeability, as well as excellent mechanical properties. It is mainly used in food packaging, water pipes, general buildings and more. It has the following features: 1) Excellent corrosion resistance 2) Good heat-resistance 3) Excellent impact resistance 4) Low permeability 5) Good mechanical properties 6) Excellent chemical resistance

---

Our Hdpe Pipe is a top-quality, high-density polyethylene pipe that can withstand extreme temperatures and pressures. This durable pipe is perfect for transporting gas, water, and oil withstanding the weight of heavy machinery and vehicles.

---

HDPE pipes are made of high-density polyethylene resin and are suitable for both hot and cold water. With a variety of sizes, thicknesses, and lengths available, these pipes can be used in a wide range of industries.

---

Hdpe is an abbreviation of “high-density polyethylene”. This type of piping is made from a high-density, heat resistant plastic. HDPE pipe is used for transporting and storing liquids such as water, oil, or fuel. It is also used to transport gases and even steam. In addition to its durability, Hdpe pipe is also lightweight and easy to install due to its smooth and flexible surface. Another advantage of this type of piping is that it can be easily joined together without the need for specialized tools or extra steps. HDPE pipe is typically sold in either smooth or corrugated shapes. Smooth pipes are easier to install since they can be connected with standard construction materials like glue and nails. Corrugated pipes, on the other hand, require special tools like expanding sleeves to join them together in order to prevent leaks and other potential issues.