Pipe and fittings are connected to each other by Butt and Electrofusion Fusion Welding or mechanical fittings. Pipes made from materials other than polyethylene can be connected by compression fittings, flanges or other suitable adapters made for the purpose. Connection fittings provide convenience compared to the places to be used. Currently, two methods are used in joining Hdpe pipes:

• Electrofusion (EF) Welding Machine

• Butt Welding Machine

Electrofusion Welding Machine

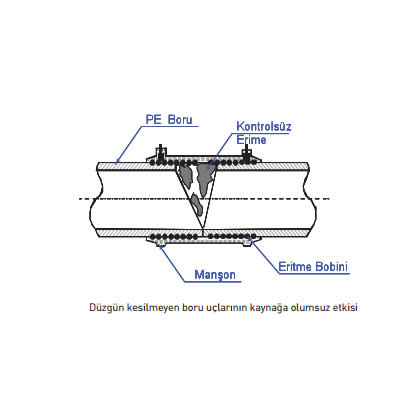

In the electrofusion welding process, welding is done with heating resistors inside the fusion fitting. Once the pipes are placed in the Ef fittings, the ends of the welding machine are connected to the resistors of the ef fitting and heating them. So, Hdpe pipe will be connected with the electrofusion fitting. Pe 100 pipes can be welded by Electrofusion welding method with Hdpe pipes of 20 mm diameter and up to 1200 mm diameter. The electrofusion welding method is carried out in accordance with DVS 2207 standard.

Butt Welding Machine

The Butt welding method is the most common welding method currently used for joining hdpe pipes and fittings. The pipe joining method is a process in which the two ends of the pipes to be heated and welded by using a butt welding machine and the both ends are pushed toward each other by pressure under a certain temperature. The butt welding method is made in accordance with DVS 2207 standard.

COMPARISON OF EF WELDING AND BUTT WELDING METHODS

Hf both weldings are made by licensed welders and in accordance with DVS 2207 standard, there is no difference in quality between the butt welding and electrofusion welding methods.

Make sure that the right method is used in the right place to get the best performance from the work done.

The butt welding method is more advantageous comparing to the ef welding by seeing the welding position.

Electrofusion welding is more advantageous when it is necessary to weld in high ground or where welding machine can not fit.

It is more advantageous to obtain the welding operation according to the degree of convenience.

In the electrofusion welding method, the factors determining weld quality are higher than those of the butt welding (pipe ovality, electrical voltage and continuity, measurement tolerances, etc.). therefore, the butt welding is more advantageous than the electrofusion welding.

In terms of welding cost, the butt welding is more advantageous than the electrofusion welding.

Electrofusion welding is more advantageous in view of after welding procedure image.

2022 Butt Welding Machines Price List

Here are the current 2022 Butt Welding Machines Price list. Contact us to get best price and you can take an information by calling +90 382 266 23 03 or export@kuzeyborugroup.com.

.png)

.png)

.png)

.png)

.png)

_(6).png)

Kuzeyboru hdpe pipe welding machiness will be indispensable for your projects with high quality and reasonable price. Get in touch immediately.